Solutions for Additive Manufacturing

A range of design, simulation, manufacturing and quality inspection solutions specifically created to optimize design and manufacturing.

3D Printing: Design and Manufacture, right first time

Leveraging the huge potential of additive manufacturing requires proper design and expertise throughout the entire process chain. Tweaking the design manually for additive manufacturing is time-consuming, error-prone and the production can cause costly defects.

On this page, you will find solutions for stable AM design and manufacturing. From optimized, lightweight designs with generative design, validation and manufacturing process simulation for optimal quality and hassle-free production, to tools ensuring high-quality end parts.

Design for Additive Manufacturing (DfAM)

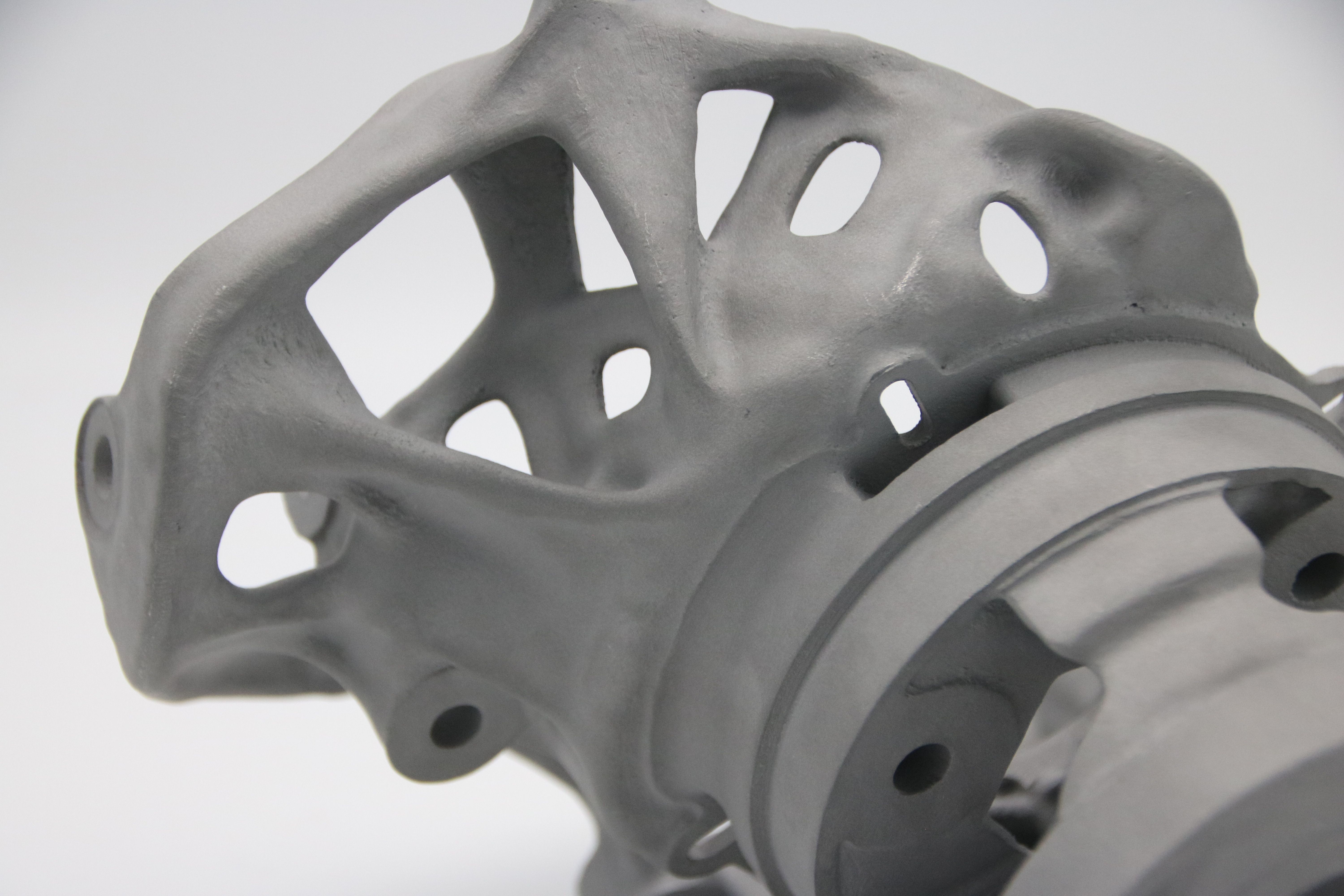

Create lightweight, print-ready designs tailored for additive manufacturing using generative design. Then, prepare for production and virtually print your part to identify potential manufacturing issues.

Generative Design

Materials Management

Additive Manufacturing

Virtual Manufacturing & Costing

Dimensional Analysis

NDT

Optimize design for additive manufacturing parts with no FEA expertise. Ensure manufacturability and print right first time by mitigating production issues and compensating part distortion virtually.

Ensure material compliance

Avoid data loss and enable workflow automation

Enable true collaboration across the entire workflow

Products used

GD&T and NDT part quality inspection

Ensure the dimensional integrity of complex part geometries and avoid product failures caused by internal defects, with just one inspection solution. Comprehensive metrology and NDT solutions to inspect both outer and inner geometries of your additive manufacturing part, and identify potential internal material defects such as porosities and inclusions.

Dimensional Analysis

CT Analysis

Products used

© 2024 Hexagon AB and/or its subsidiaries